Question

a.

1

b.

10

c.

20

d.

30

Posted under Heat Transfer Basics Basic Chemical Engineering

Interact with the Community - Share Your Thoughts

Uncertain About the Answer? Seek Clarification Here.

Understand the Explanation? Include it Here.

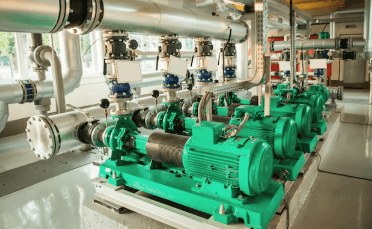

Q. Maximum water velocity in tubes of a 1-2 shell and tube heat exchanger may be around __________ metres/second.

Similar Questions

Explore Relevant Multiple Choice Questions (MCQs)

Q. In Biot number, the characteristic length used is the ratio of the __________ of the solid.

View solution

Q. Which of the following is the most widely used heat insulating material for pipelines carrying steam ?

View solution

Q. Heat transfer co-efficient equation for forced convection, Nu = 0.023 Re^0.8 . Prⁿ, is not valid, if the value of

View solution

Q. Which is the best tube arrangement (in a shell and tube heat exchanger) if the fluids are clean and non-fouling ?

View solution

Q. In case of a multipass shell and tube heat exchanger, the temperature drop in the fluid

View solution

Q. Reason for operating an evaporator in multiple effect is to secure

View solution

Q. In a cooling tower, water becomes cool by

View solution

Q. In Fourier's law, the proportionality constant is called the

View solution

Q. The heat transfer co-efficient in film type condensation is __________ that for dropwise condensation.

View solution

Q. Pick out the wrong statement.

View solution

Q. 'Duhring's plot' is of use in

View solution

Q. Which has the lowest Prandtl number ?

View solution

Q. Pick out the wrong statement.

View solution

Q. Prandtl number for most of dry gases is about

View solution

Q. Prandtl number is the reciprocal of

View solution

Q. The purpose of providing expansion bellows in the shell of tubular exchanger is to

View solution

Q. Grashhoff number is given by

View solution

Q. The overall heat transfer co-efficient for a shell and tube heat exchanger for clean surfaces is U0 = 400 W/m².K. The fouling factor after one year of operation is found to be hd0 = 2000 W/m².K. The overall heat transfer co-efficient at this time is

View solution

Q. In a laboratory test run, the rate of drying was found to be 0.5 x 10⁻³ kg/m².s, when the moisture content reduced from 0.4 to 0.1 on dry basis. The critical moisture content of the material is 0.08 on a dry basis. A tray dryer is used to dry 100 kg (dry basis) of the same material under identical conditions. The surface area of the material is 0.04 m²/kg of dry solid. The time required (in seconds) to reduce the moisture content of the solids from 0.3 to 0.2 (dry basis) is

View solution

Recommended Subjects

Are you eager to expand your knowledge beyond Basic Chemical Engineering? We've handpicked a range of related categories that you might find intriguing.

Click on the categories below to discover a wealth of MCQs and enrich your understanding of various subjects. Happy exploring!