Question

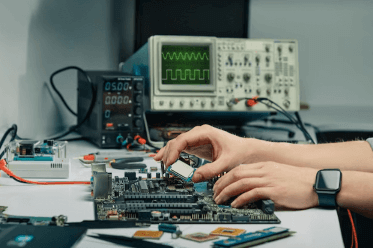

a.

grinding

b.

lapping

c.

honing

d.

buffing

Posted under Mechanical Engineering

Interact with the Community - Share Your Thoughts

Uncertain About the Answer? Seek Clarification Here.

Understand the Explanation? Include it Here.

Q. In order to obtain a surface finish in the range of 0.75 μm to 1.25 μm , the operation used is called.

Similar Questions

Explore Relevant Multiple Choice Questions (MCQs)

Q. The angle between the face and flank of the single point cutting tool is known as

View solution

Q. The parameter which completely defines the chip formation in a metal cutting process is

View solution

Q. A lathe with four steps on the cone pulley and with backgears will have

View solution

Q. The increase in depth of cut and feed rate __________ surface finish.

View solution

Q. Holes are machined by push broaches only for sizing.

View solution

Q. In gear hobbing

View solution

Q. EDM machining is applied for

View solution

Q. A fine grained grinding wheel is used to grind

View solution

Q. When the shear angle is small

View solution

Q. In oblique cutting system, the cutting edge of the tool

View solution

Q. Hard and tough materials like cast iron should be turned at

View solution

Q. The cutting speed for counter-boring should be __________ that of drilling operation.

View solution

Q. The usual value of the helix angle of a drill is

View solution

Q. Glazing in grinding wheels __________ cutting capacity.

View solution

Q. In the relation VTn = C, the value of n for high speed steel tools varies from 0.25 to 0.40.

View solution

Q. The enlarging of an existing circular hole with a rotating single point tool is called

View solution

Q. A bottoming tap has

View solution

Q. Negative rakes are used for

View solution

Q. The chuck preferred for quick setting and accurate centering of a job is

View solution

Q. The tail stock set over method of taper turning is preferred for

View solution

Recommended Subjects

Are you eager to expand your knowledge beyond Mechanical Engineering? We've handpicked a range of related categories that you might find intriguing.

Click on the categories below to discover a wealth of MCQs and enrich your understanding of various subjects. Happy exploring!